The world’s leading manufacturer of respirator masks may have originally intended them to be bras. So could bra makers help address desperate clinical shortages?

3M patented a bra design in the 1960s but then – possibly due to the bra-burning 1970s – is said to have reinvented the moulded cups as masks.

“Legend has it, 3M’s protective breathing devices were originally conceived in the 1960s as molded, non-woven brasserie cups,” according to a 2009 article in Chemical and Engineering News.

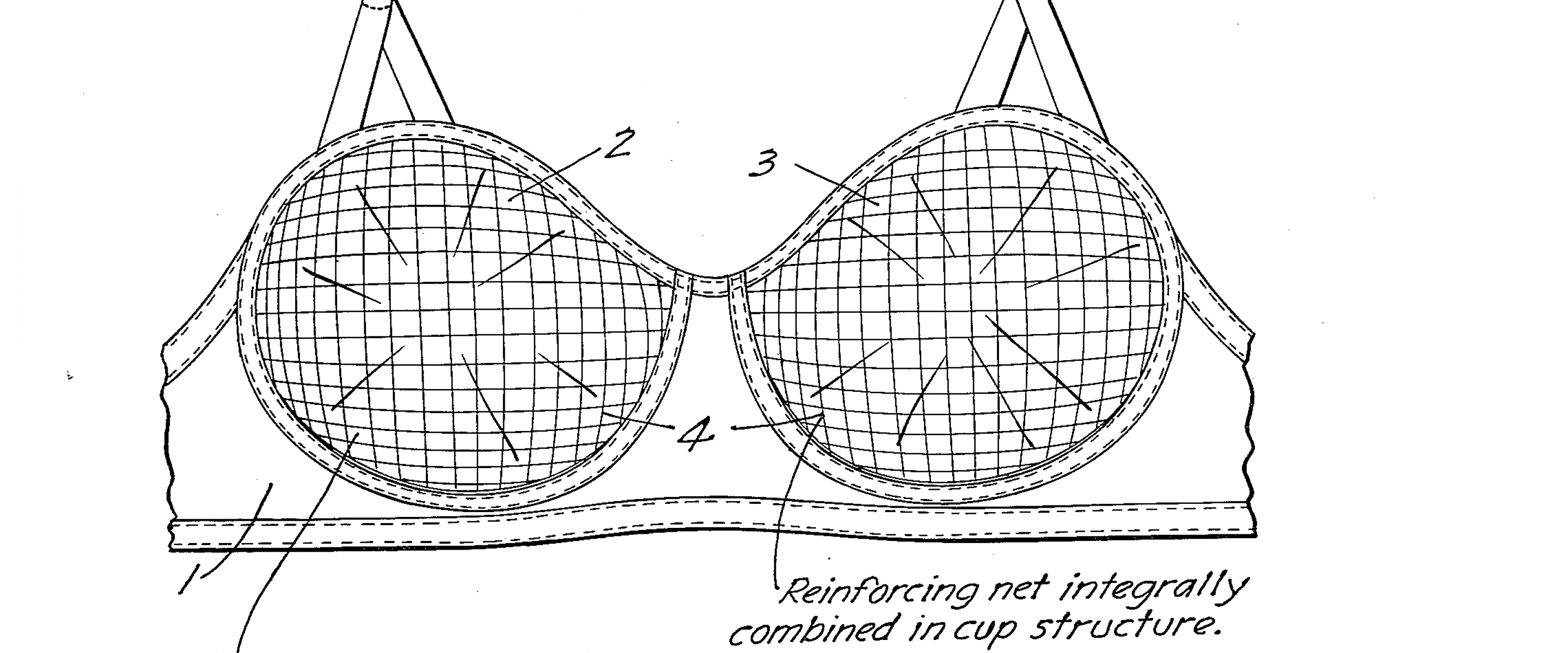

3M’s patent (US Patent No. 3,064,329) outlines a bra as the principal product for its method of heat-moulding polyester fibers into three-dimensional forms, complete with a drawing. However, the patent adds: "Examples of shaped articles of wearing apparel other than brassiere cups that can be manufactured to advantage in accordance with this invention, are: contoured shoulder pads and hip forms, employed in clothing; hat and cap crowns; slippers; tennis shoe uppers; and porous breath-filtering face masks used by surgeons, physicians, dentists, nurses, and by industrial workers subjected to dusty or contaminated atmospheres."

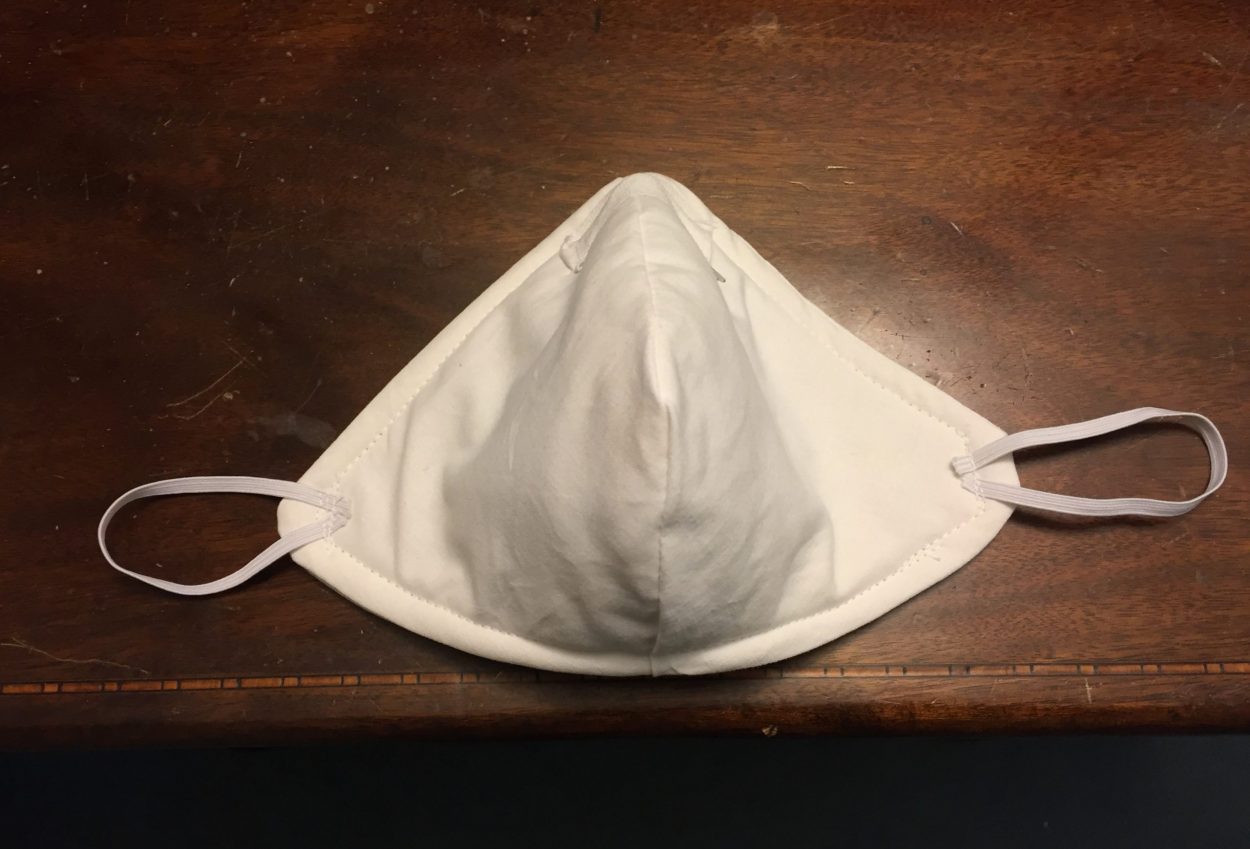

This raises the possibility that bra makers – particularly those that make moulded bras – could already be partially tooled to manufacture masks (just as gin distilleries are able to produce hand sanitizer).

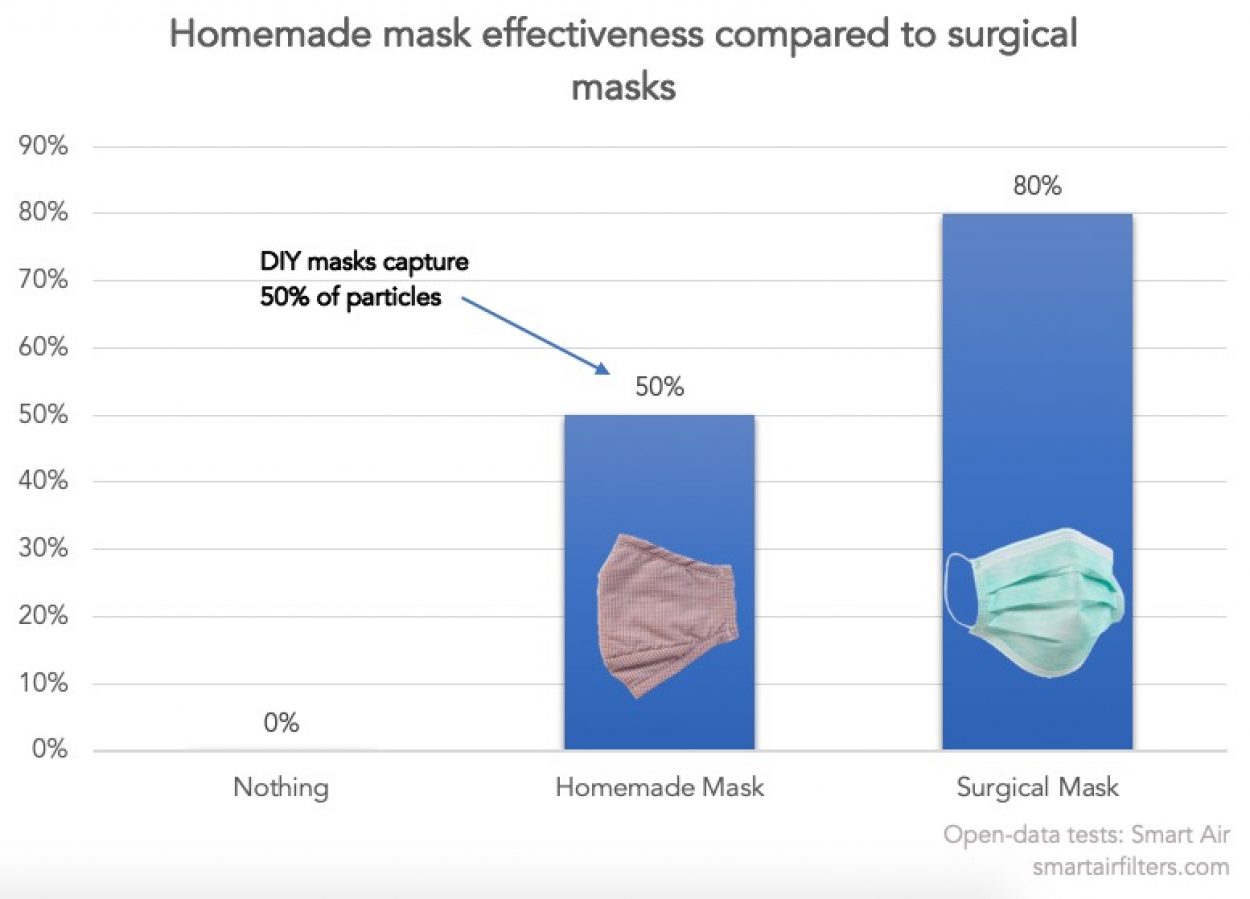

Masks to protect doctors and nurses are in desperately short supply. In the US, hospital workers are already making them using parts from craft stores and have been warned they may even have to improvise with bandanas. Some are asking the public to sew CDC-compliant face masks. Meanwhile, in the UK an ENT surgeon is on life support and there are fears more medics will fall ill. Some doctors and nurses have resorted to sharing masks or buying their own from DIY stores (although these have now sold out).

Most of the world's masks are manufactured in China which has restricted exports. NHS doctors are calling for the government to convert British factories to manufacture masks and other protective equipment in addition to ventilators.

"We are hearing of staff trying to buy masks from DIY stores in desperation because they are not being provided with it by their employers," said Dr Chaand Nagpaul, the BMA chair of council.

"The Government must find a reliable way to increase the production and distribution of PPE [personal protective equipment]."

Storytelling for Marketers

The Wonderful Wizard of OzStorytelling for Leaders

Moby DickStorytelling For Lawyers

Alice’s Adventures in Wonderland